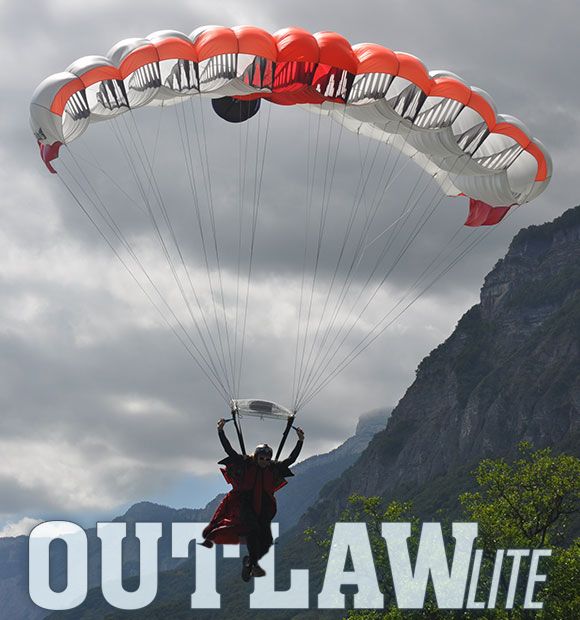

The OUTLAW LITE is the lightweight, low-pack-volume version of the OUTLAW. There are many benefits to lightweight cloth in BASE canopy design, and we encourage all jumpers to consider the light version for the following reasons:

- Reduced canopy inertia during the extraction and expansion phase means better openings, better heading performance.

- Faster extraction: A lighter parachute can be extracted more efficiently and has an advantage over standard weight canopies in the first seconds of deployment.

- Easier to pack: Porcher PN9 lies flatter, has less tendency to expand or squirm, and is easier to fold.

- Easier to carry: Everyone likes arriving at the exit point with a bit more energy.

- The lower pack volume of PN9 allows a slimmer, more aerodynamic container.

- Read this article for more info on light fabric.

The OUTLAW LITE is not designed especially for alpine or wingsuit applications. We believe the light option should be seriously considered by all jumpers, including those who mainly jump slider down objects.

Since its release the OUTLAW and OUTLAW LITE have become known for excellent deep brake behavior, extremely low forward speeds at opening, and stable characteristics.

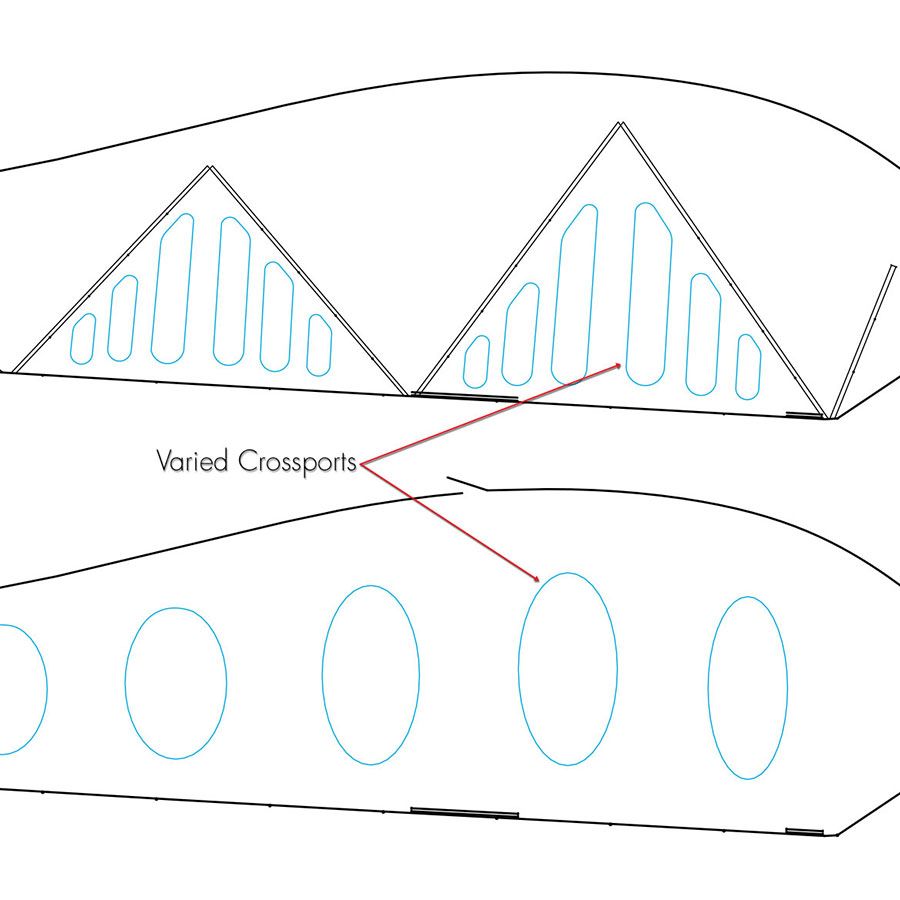

- 5 mini-vents at A-chord line for forward A-line attachment

- Rear-chord Float-Flaps

- Center-cell slat system

- Varied crossports

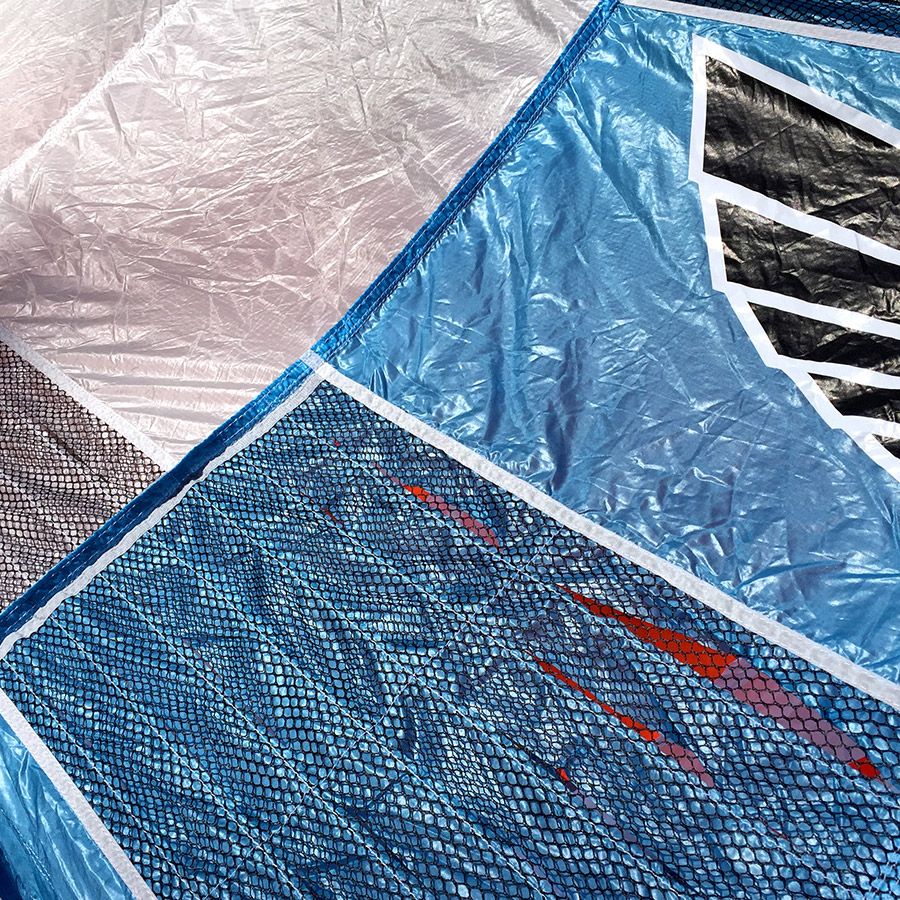

- ZP Ellipse at leading edge

- Staggered upper brake cascade